By SEOCH

•

February 22, 2026

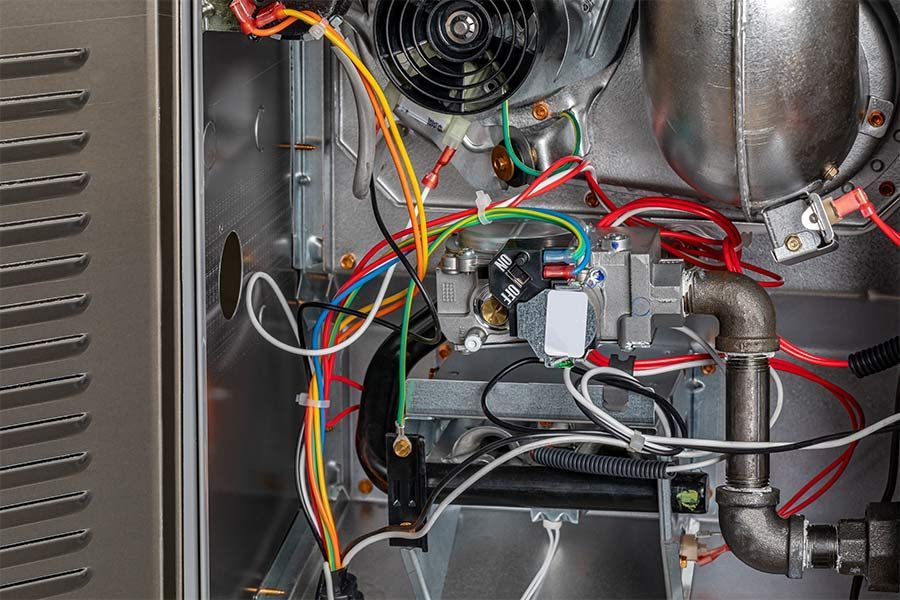

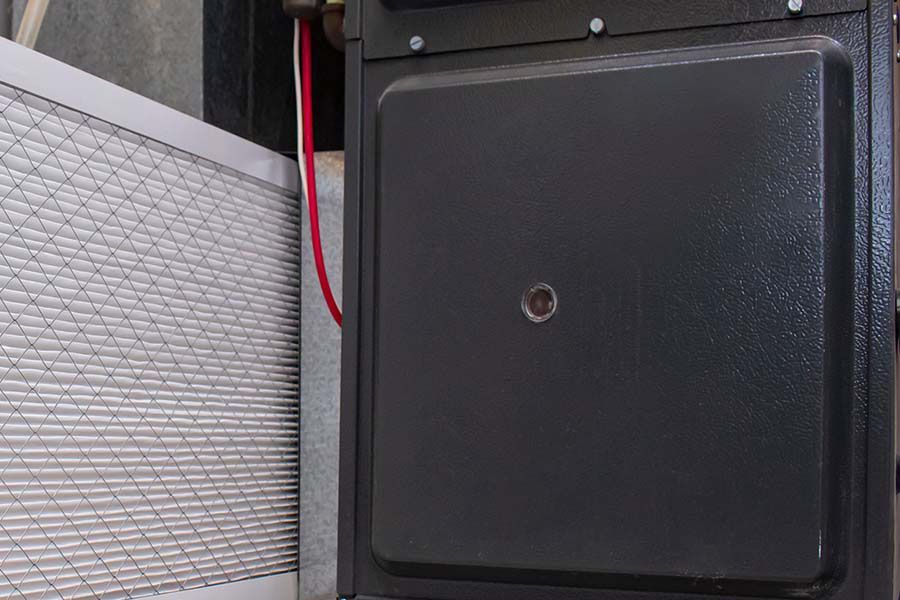

When it comes to your furnace, scheduling regular maintenance in Richmond, KY, can make a significant difference. You'll benefit from increased energy efficiency and potentially lower utility bills. Plus, routine check-ups can extend your furnace's lifespan and improve indoor air quality. But that's just the beginning. There are several other advantages you might not have considered that could enhance your home comfort and safety. Let's explore what they are. Increased Energy Efficiency When you prioritize furnace maintenance, you'll notice increased energy efficiency in your home. Regular check-ups help your system run smoothly, reducing energy consumption and lowering utility bills. A well-maintained furnace burns fuel more effectively, guaranteeing you get the most heat for every dollar spent. During maintenance, professionals clean crucial components, check for leaks, and replace worn parts, all of which contribute to peak performance. This proactive approach not only saves you money but also enhances your comfort by delivering consistent warmth throughout your living spaces. Additionally, scheduling a tune-up can extend furnace life and prevent costly repairs, ensuring your system remains reliable for years to come. With reduced energy use, you're also doing your part for the environment, cutting down on emissions and resource consumption. Extended Furnace Lifespan Regular furnace maintenance is key to extending your system's lifespan. By investing in preventative care, you not only boost efficiency but also protect your investment for years to come. Taking these steps now can save you from costly repairs and replacements later. Additionally, addressing issues early can prevent major repairs and enhance your heating system's performance . Preventative Care Benefits Investing in preventative care for your furnace not only enhances its efficiency but also greatly extends its lifespan. By scheduling regular maintenance, you're ensuring that small issues are identified and resolved before they escalate into costly repairs. Routine check-ups keep your system running smoothly, reducing wear and tear on essential components. When your furnace operates at its best, it's less likely to break down unexpectedly, saving you from the hassle and expense of emergency repairs. Additionally, a well-maintained furnace can last years longer than one that's neglected. Prioritizing preventative care means you'll enjoy consistent comfort in your home while maximizing your investment. Trusting professionals like Watson Heating & Air can help you achieve these benefits effortlessly. Efficiency Improvement Scheduling routine maintenance doesn't just prevent problems; it appreciably boosts your furnace's efficiency. When you keep up with regular check-ups, your system runs smoothly, using less energy to heat your home. This efficiency translates to lower utility bills, which is a win for your wallet. Additionally, a well-maintained furnace experiences less wear and tear, extending its lifespan considerably. Regular inspections help identify and fix minor issues before they escalate, ensuring your furnace operates at peak performance. You'll enjoy consistent warmth and peace of mind, knowing your heating system is in top shape. With Watson Heating & Air, you can trust that your furnace maintenance is handled with care, helping you create a comfortable and efficient home environment. Enhanced Indoor Air Quality Regular furnace maintenance can greatly boost your indoor air quality by reducing allergens and pollutants. You'll notice improvements in humidity control and ventilation efficiency, making your home more comfortable and healthier. Investing in this upkeep guarantees you breathe easier and enjoy a fresher living environment. Additionally, regular maintenance can help identify issues with clogged ductwork , ensuring your furnace operates efficiently and safely. Reduced Allergens and Pollutants When you prioritize furnace maintenance, you not only guarantee your heating system operates efficiently but also greatly improve your home's indoor air quality. A well-maintained furnace helps reduce allergens and pollutants that can accumulate in your living space. During maintenance, your technician will clean or replace the air filters, removing dust, pet dander, and mold spores that can trigger allergies and respiratory issues. Additionally, routine checks make certain that the furnace is venting properly, preventing harmful gases from circulating indoors. By investing in regular maintenance, you create a healthier environment for your family, making it easier to breathe and enjoy your home. Don't overlook this vital aspect—your comfort and well-being depend on it! Improved Humidity Control Maintaining your furnace goes beyond just improving air quality by reducing allergens and pollutants; it also plays a significant role in managing humidity levels in your home. When your furnace is well-maintained, it helps regulate moisture in the air, preventing it from becoming too dry or overly humid. This balance is essential for comfort and health, as excessive humidity can lead to mold growth and discomfort, while low humidity can cause dry skin and respiratory issues. With regular maintenance, your furnace operates efficiently, guaranteeing ideal humidity control. Enhanced Ventilation Efficiency Enhanced ventilation efficiency is essential for achieving ideal indoor air quality in your home. When you schedule regular furnace maintenance, you're ensuring that your system operates at its best, allowing fresh air to circulate effectively. This helps reduce indoor pollutants and allergens, making your living space healthier for you and your family. A well-maintained furnace also prevents dust and debris buildup in the ventilation system, enhancing airflow and reducing the risk of respiratory issues. By prioritizing maintenance, you're investing in a more comfortable and safe environment. Plus, with Watson Heating & Air's commitment to quality service, you can trust that your home's ventilation will be optimized for maximum efficiency. Don't overlook this vital aspect of your home's health! Early Detection of Potential Issues By catching potential issues early, you can prevent costly repairs and guarantee your furnace operates efficiently throughout the colder months. Scheduling regular maintenance allows a technician to inspect your system thoroughly, identifying worn-out parts or minor malfunctions before they escalate into major problems. You're not just prolonging the life of your furnace; you're also ensuring it runs smoothly when you need it most. During maintenance checks, professionals can spot issues like loose connections, dirty filters, or malfunctioning components that might go unnoticed otherwise. Additionally, regular maintenance helps ensure fast response times for urgent heating needs, allowing you to address potential issues before they become significant concerns. Addressing these concerns promptly means you won't face unexpected breakdowns on freezing nights. Plus, you'll likely save money in the long run by avoiding emergency repairs. Improved Safety and Reduced Risk When you schedule regular furnace maintenance, you help guarantee your home's safety by detecting carbon monoxide leaks early. This proactive approach also assures proper ventilation flow, reducing the risk of dangerous buildups. Keeping your furnace in check not only protects your family but also gives you peace of mind. Detect Carbon Monoxide Leaks How can you guarantee your home remains a safe haven? Scheduling regular furnace maintenance is an essential step. During these check-ups, professionals can detect carbon monoxide leaks before they pose a serious threat to you and your family. This colorless, odorless gas can be deadly, making it critical to verify your furnace operates safely. By catching leaks early, you're not only protecting your loved ones but also enhancing the overall efficiency of your heating system. Regular maintenance means peace of mind, knowing your furnace won't put your safety at risk. Trust Watson Heating & Air to provide thorough inspections, confirming your home remains a secure and comfortable environment for everyone. Prioritize your safety with routine furnace maintenance today! Ensure Proper Ventilation Flow Ensuring proper ventilation flow is essential not only for your furnace's efficiency but also for your family's safety. When your furnace has adequate airflow, it operates more efficiently, reducing the risk of overheating and potential breakdowns. During maintenance, professionals check and clean vents, ensuring they're clear of obstructions that could lead to dangerous situations, like carbon monoxide buildup. You'll also lower your energy bills since a well-ventilated system uses less energy to maintain comfort. Scheduling regular furnace maintenance with Watson Heating & Air guarantees these checks are done, giving you peace of mind. Prioritizing ventilation flow means prioritizing your family's well-being—so don't wait to schedule that maintenance appointment! Lower Energy Bills While regular furnace maintenance might seem like an added expense, it can actually lead to significant savings on your energy bills. When you schedule maintenance, you guarantee that your furnace operates efficiently, reducing the amount of energy it consumes. A well-maintained system runs smoothly, which means it doesn't have to work as hard to heat your home, translating to lower energy costs. Additionally, maintenance helps identify and address potential issues before they escalate, preventing costly repairs and energy waste. Dirty filters, for instance, can restrict airflow, causing your furnace to use more energy than necessary. By keeping your furnace clean and well-tuned, you not only enhance its lifespan but also optimize its performance. Ultimately, investing in regular maintenance with Watson Heating & Air can be a smart financial decision, allowing you to enjoy a cozy home without breaking the bank on energy bills. Peace of Mind Regular furnace maintenance not only saves you money on energy bills but also brings you peace of mind. Knowing that your heating system is in excellent condition allows you to relax, especially during the cold months. You won't have to worry about unexpected breakdowns or rising repair costs. When professionals like Watson Heating & Air handle the maintenance, you can trust that they'll spot potential issues before they become major problems. This proactive approach means you're less likely to face an emergency during the winter, ensuring your home stays warm and comfortable. Regular check-ups also improve your furnace's longevity, letting you enjoy a reliable heating source for years to come. Plus, you'll feel secure knowing that your indoor air quality is being monitored and maintained. In short, regular maintenance provides not just warmth, but also the reassurance that your family is safe and cozy all winter long. Priority Service for Members Being a member of Watson Heating & Air's Preferred Member Club means you'll enjoy priority service whenever you need it. This exclusive membership guarantees that when your furnace acts up, you won't be left waiting in the cold. You'll receive top-of-the-line service, with your calls prioritized over non-members. Imagine needing a repair, and within hours, a skilled technician is at your door. That's the peace of mind you get with priority service. Plus, our members have access to diagnostic perks that help identify issues before they escalate, keeping your furnace running smoothly. Your home's comfort is our priority, and with our exceptional response times, you'll never feel neglected. Enjoy the extra level of care that comes with being a Preferred Member. Trust us to keep your furnace in top shape, so you can focus on what matters most—your family and your comfort. Warranty Protection When you choose Watson Heating & Air, you gain the peace of mind that comes with warranty protection on all our installations and repairs. This means that should anything go wrong after we've completed the work, you won't have to worry about unexpected costs. Our warranties cover various issues, ensuring you're protected against defects and shortcomings. By scheduling regular furnace maintenance, you further safeguard your investment. Routine checks help identify potential problems before they escalate, keeping your warranty intact. You'll not only enjoy the comfort of a well-functioning furnace but also the assurance that you're covered if issues arise. This warranty protection reflects our commitment to quality and customer satisfaction. It's our way of ensuring that you feel secure in your choice, knowing that we stand behind our work. With Watson Heating & Air, your comfort is our priority, and we're here to support you every step of the way. Expert Maintenance and Care Maintaining your furnace isn't just about ensuring it runs; it's about maximizing its lifespan and efficiency. When you choose expert maintenance from Watson Heating & Air, you're not just getting a service; you're investing in peace of mind. Our team knows the ins and outs of your system, ensuring every component works effectively. Regular check-ups help identify potential issues before they escalate, saving you time and money in the long run. You'll benefit from our honest, affordable solutions, guaranteeing you're never caught off guard with unexpected costs. Plus, our Preferred Member Club offers priority service and diagnostic perks, ensuring you're always at the front of the line when you need us. With our commitment to courteous service and quality care, your furnace will operate efficiently, keeping your home comfortable for years to come. Don't leave your comfort to chance; trust the experts at Watson Heating & Air.